Business Area

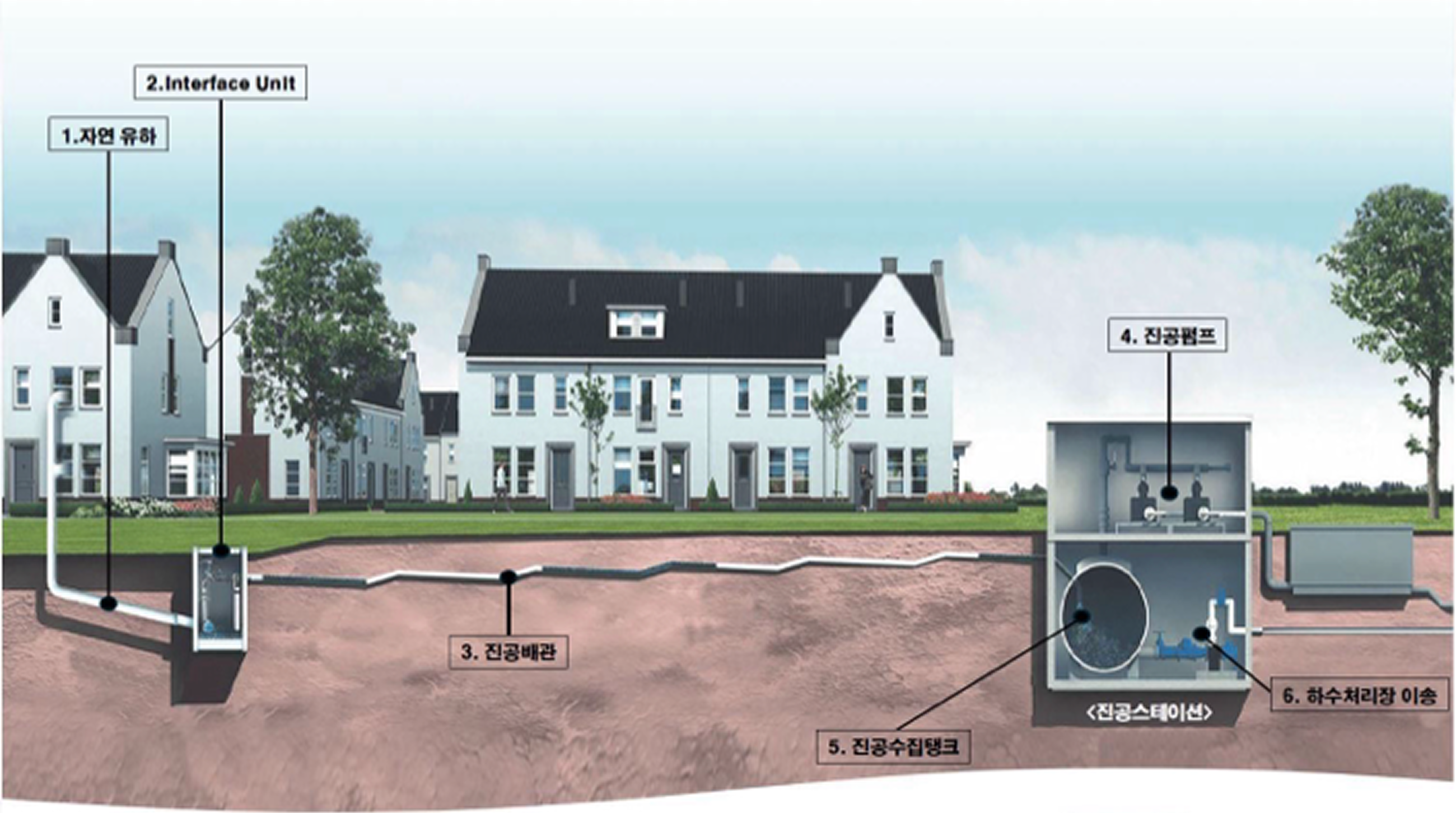

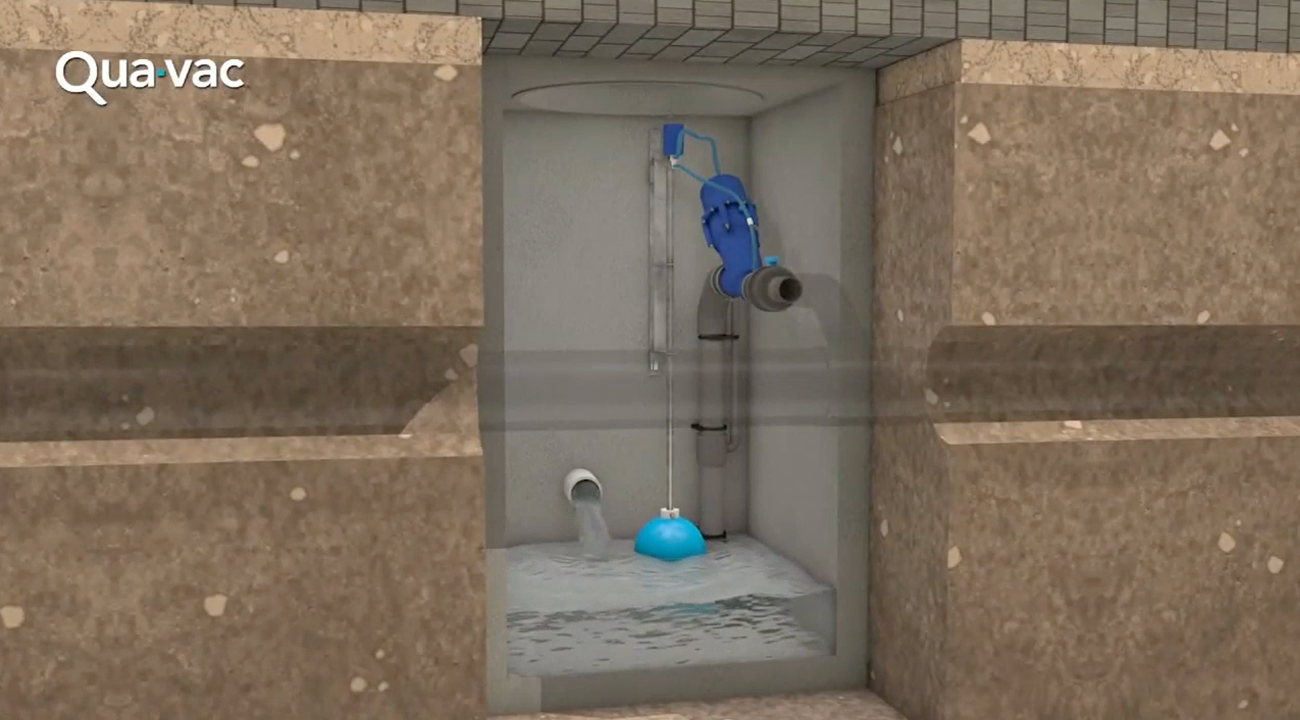

Vacuum pressure is a method of transporting wastewater to a vacuum pump station

through a

closed pipeline.

In particular, in areas where natural flow is difficult, such as soft ground, rocky

areas,

and areas with high groundwater levels,

economical and

efficient wastewater transport is possible.

An innovative wastewater collection system provides stable operation that takes into environmental protection and constructability

Numerous lift stations with their high capital cost and maintenance requirements are utilized to offset excessive excavation and trenching costs.

Excavating in areas of high water table is expensive due to complicated and time constuming dwatering and trench stabilization procedures.

Wide and deep trenches often make roads impossible to pedestrians and vehicular traffic for ling periods if time. Damage to tree and landscaping can be severe.

Exfiltration can contaminate the surrounding arean (water sourece, lakes and rivers).n Infiltration is a serious problem resulting in existingn treatment becoming hydraulically overloaded andn the imposition of compulsory over-sizing of treatment plants under desig

Unforeseen obstructions such as water or sewer mains, large rocks, etc. usually result in expensive field changes and line rerouting.

200 mm up to 400 mm diameter concrete pipe and vitrified clay pipe sewer main are typocal with material costs and excessive unit labour costs.

Non-continuous slope allows shallow trenching to be used resulting in substantial excavation cost savings and reduced installation time.

Eliminating and/or minimizes dewatering and trench stabilization problems

Small diameter mains, installed just below frost level allow shallow and narrow trenching thereby minimizing construction time and environmental disturbances.

Absolutely fail-safe - field tested and operated under vacuum conditions. A broken main, at worst, results in infiltration (easily detected) - ever exfiltration.

Vertical lift capability allows unforeseen obstructions to be easily passed over, under, or around resulting in minimum delay and eliminating extra costs.

90 mm up to 200 mm diameter PVC or HDPE vacuum sewer mains are typical. Labour and materials costs for installing vacuum piping are dramatically lower, compared to gravity sewers, due to labour and trenching costs associated with smaller diameter vacuum main.

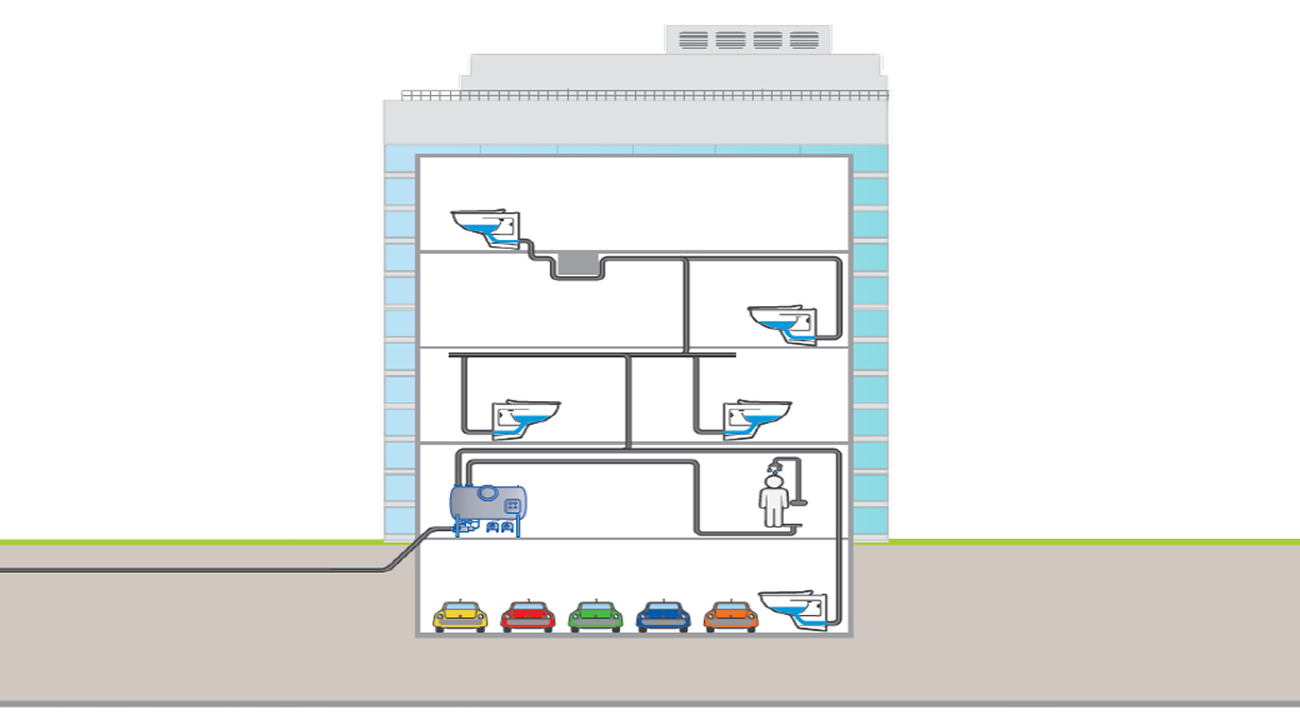

The vacuum toilet system is an innovative sanitary facility that transports wastewater using vacuum pressure rather than relying on gravity. It is capable of powerful cleaning with a small amount of water, and can be flexibly applied even in spaces where existing gravity toilets are difficult to install, so it is gaining attention in various building environments.

Up to 90% water savings compared to regular toilets, especially in commercial facilities, hospitals, and hotels where toilets are used a lot, maximizing economic effects

The higher the water usage, the shorter the ROI (return on investment) Simplified maintenance, reduced wastewater treatment costs

Prevents overspray (water droplets) → Prevents the spread of viruses and bacteria Uses antibacterial materials and has a 99.99% bacteria removal effect Provides a pleasant bathroom environment with an odorless system

No need for pipe slope, design possible regardless of discharge point, easy to install in basements, remodeled buildings, mobile buildings, etc. Vacuum pipes are small in diameter (50~75mm) and have a space-saving effect

G-SEED store elements, etc., are advantageous in obtaining eco-friendly building certification

- Model name

- Evac Optima series

- Water usage

- 1.2~1.5L per use

- Water durability

- Over 300,000 operation tests completed

- Noise

- 62~67dB (low-noise design)

- Hygiene

- NSF standard 99.99% antibacterial

Vacuum toilet systems are more than just a simple installation they are a smart choice that meets all of the following requirements: Sustainability, Efficiency, and Flexibility